Railway R&D center

SAMPYO Railway drives changes in Korea’s railway industry and makes technological innovations through continuous R&D

Professionals from the railway engineering field are working to create a new future

SAMPYO Railway R&D Center was established in 2001 to develop the Korean railway industry. Organized by experts from the railway track area, it is performing various researches to improve the track stability and the performance of the railway.

As a fourth country to operate the HSR, it performs various HSR track component developments and successfully localized the production of HSR turnout. It is also making efforts to develop the Korean railway technology to be in line with other advanced nations around the world.

Major research areas are turnouts for conventional railways and HSR, signaling components, fasteners, special rails and others which are critical components for the railway track. To achieve such researches, the Railway R&D Center performs various activities such as 2D/3D designing, FEM and Dynamic Analysis, indoor performance tests, field construction tests and measurement tests. SAMPYO Railway R&D Center actively engages in R&D activities to advance Korean railway technology with SAMPYO Railway’s own technological prowess and know-how, which have been accumulated over a long-period of time.

Research area

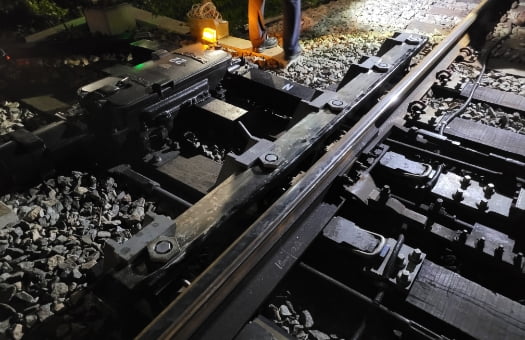

Turnout (switch)

A railway turnout (railroad switch), also known as a track switching device, is a mechanical device that guides the train from one track to another. It is also an important structure in the track system and requires high accuracy design and know-how as it is directly linked to the safety of the railway vehicle.

SAMPYO Railway R&D Center concentrates all of its technological capability in order to build the track infrastructure which ensures the safe operation of the railway vehicle at the high speed.

Railway track products

As a company specialized in manufacturing railway products, SAMPYO Railway established a research collaboration network with advanced companies overseas, as well as Korean universities and institutes to develop various railway products which suit the customer’s needs and also to develop innovative products. Moreover, it has made continuous efforts to develop key critical technology by having cutting-edge dynamic structural analysis software and labs to secure technological competiveness in the global market.

Precast Slab Track System (PSTS)

The PSTS is a railway track system that can be used immediately at the site by assembling rails, fasteners, other components and slab panels which are pre-fabricated at the factory and moved to the site. It is an outstanding system compared to the cast-in-place track construction system as it allows faster construction, uniform quality, reduced maintenance cost and precise construction.

Research area

2D & 3D designing and 3D printing technology

- Designing turnouts for Korean and overseas HSR and conventional railway

- Designing rail expansion joints

- Designing rail expansion and contraction device for a bridge

- Designing manganese steel crossing and cradle

- Designing railway turnout sleepers

- Designing various rail fastening system

- Product improvement design

- Obtained performance verification, type approval, NET Certification, quality management system certification (ISO 9001)

- Managed various standards and specifications including KRS

- Designing railway track and signaling products

- Designing turnouts for overseas market

- Checked new and improved product interface with the use of 3D modeling and printer

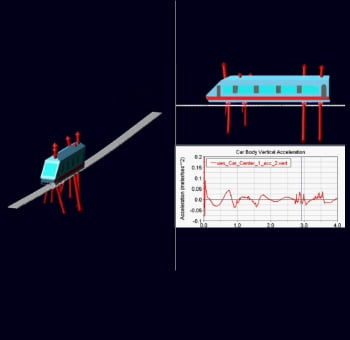

Structural analysis

- Structural safety assessment by static and dynamic structural analysis of the HSR and conventional railway products

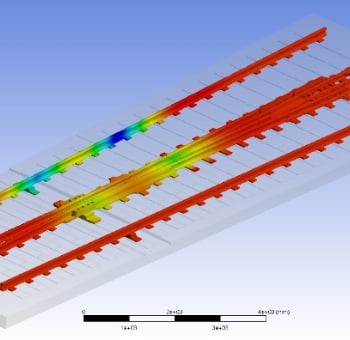

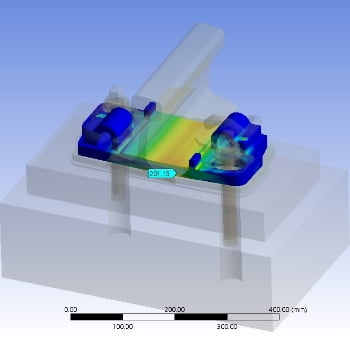

- 3D modelling of the turnouts and conducting static structural analysis on turnouts

- Static and dynamic analysis with the use of structural analysis S/W

- STATIC AND DYNAMIC ANALYSIS VIA STRUCTURAL ANALYSIS S/W

- Supporting the review of the structural safety and calculating the structure for turnout sleepers and track components

Indoor performance verification and field measurement

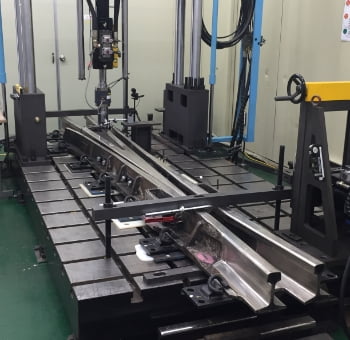

- Conducted the rail fastener test based on the KRS TR 0014 (repeated load test, static and dynamic vertical stiffness test on single and assembled product)

- Conducted various domestic and foreign standard compliance test (KRS, KS, EN and others)

- Conducted field measurement test and monitoring (system of measuring on-track driving)

- Measured with a track master, measuring the wear of the rail, track alignment, etc.

- Conducted durability assessment test on products (destructive and non-destructive test)

New technology and certification

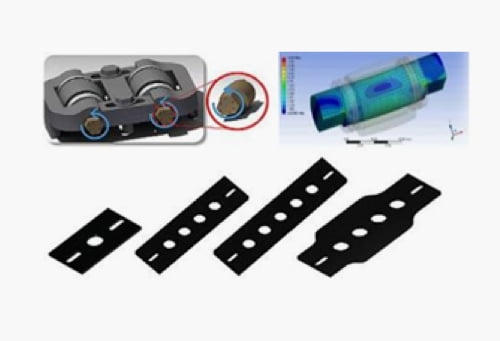

Technology to adjust the stiffness of a double elastic fastening device applied to turnouts of a railway track for the concrete track with the surface area of an elastic pad (2010)

Technology to build a rail fastening device for turnout where bush tooth washer adjustment is equipped (2019)