Railway

Leading the Korean and global railway markets based on the technological competitiveness and the networking

No. 1 railway track engineering company in Korea

SAMPYO Railway, which started as a railway division in Gangwon Industry Co., Ltd. in 1980, has been with the development of the Korean railway and its history.

In 1997, SAMPYO Railway established a railway turnout (railroad switch) manufacturing plant for the first time in Korea and equipped with a mass production system for various track components including railway turnout which is a core product in the railway track field. It also secured world-class technology through active technological development and decisive investments. Based on the global competitiveness gained through continuous efforts, SAMPYO Railway is actively entering overseas market and receiving favorable reviews from clients for its technology and quality.

Starting with manufacturing railway track components including railway turnouts, SAMPYO Railway has grown into a comprehensive railway engineering company encompassing all areas of the railway track sector, including railway track construction, production and construction of pre-cast concrete slab track (PST) panels, rail grinding, facility maintenance works and other railway track related activities.

SAMPYO Railway will strive to grow into a global company through strict quality control, differentiated customer service, decisive investment and active market development without making compromises.

Railway track products and services with an excellence

Railway track products (turnouts)

Railway turnout is a mechanical installation enabling railway trains to be guided from one track to another. It is an important comprehensive structure for the track and signal sector.

SAMPYO Railway is leading the Korean railway track component market including railway turnouts based on its technological competitiveness. Starting with the installation of the high-speed railway (HSR) turnouts for Gyeongbu HSR, SAMPYO Railway localized the production of the concrete-tracked HSR turnouts for the first time in Korea and installed them into the Honam HSR. These contributed to improve the railway turnout technology and railway safety in Korea, and also improved the market competitiveness of the Korea’s railway track component industry.

SAMPYO Railway’s competitiveness leaded it to enter into the global railway track component market. It is continuously expanding its presences and making exports to overseas markets such as Taiwan R.O.C, Pakistan, Iran, Philippines, Vietnam and others. SAMPYO Railway is delivering the excellence of the Korean railway track products throughout the world by exporting the products to the world. Especially in 2021, SAMPYO Railway rapidly expanded its volume of sales through awarding the contract to supply over 1,600 sets of railway turnouts to Taiwan Railway Administration.

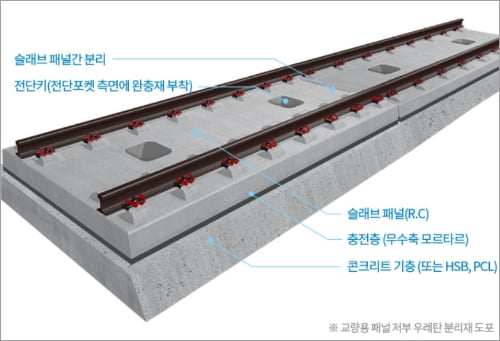

Precast concrete Slab Track System (PSTS)

With more than a decade of efforts and investments, SAMPYO Railway has commercialized the Pre-cast concrete Slab Track System (PSTS) which is a system that constructs the track on-site with pre-fabricated concrete slab panels from a plant. This system changed the paradigm of the Korean track construction technology as it overcame the issue of securing uniform quality which is a disadvantage of the conventional on-site construction method.

SAMPYO Railway is making its contributions to raise the quality of Korea’s railway track industry in all aspects including eco-friendliness, workability, economic efficiency, quality and maintenance.

SAMPYO Railway opened a Korea’s first dedicated production line for PSTS in 2013 in order to manufacture standardized products. It also plays an active role as a partner to build the national railway network such as Wonju-Jecheon, Jinju-Gwangyang, and Singyeongju-Pohang lines.

Rail Grinding/Maintenance

Rail grinding is a maintenance technology that allows the user to keep maintaining the quality of rail by precisely grinding and wiping the roughened surface of the railhead.

In 2013, SAMPYO Railway introduced and operated 30-stone rail grinding machine and introduced additional rail grinding machines (24-stone) and they helped to enhance the comfort and safety of the train operation.

Also, SAMPYO Railway participated in the rail facility maintenance sector to set the new criteria at the maintenance sector.

Railway track construction

Railway track construction is a key construction process as it directly affects the safety and comfort of the train operation. It is used to construct the structure which enables the train to ride on by combining rails, sleepers, fasteners and other components.

SAMPYO Railway has been recognized as a top-tiered company in terms of track construction in Korea by successfully completing railway construction projects including not only large-scale HSR projects such as Gyeongbu and Honam HSR but also conventional and light railways.

SAMPYO Railway R&D Center

SAMPYO Railway R&D Center was established in 2001 in order to develop the Korean railway industry and experts from turnouts and other railway track sectors are performing various studies in order to develop railway track components and improve the railway safety. It has successfully localized the technology to produce HSR turnouts, thus helping Korea be ranked as the world’s 4th HSR operating nation. It is also making various efforts to develop the track technology to reach the technical level of other advanced countries.

SAMPYO Railway obtained certifications for new technologies including turnouts and PSTS from Korea Agency for Infrastructure Technology Advancement (KAIA), Korea Industrial Technology Association (KOITA). It also made contributions to innovate the Korea’s railway technology by performing various railway-related R&D projects.