SAMPYO R&D center

Creating the foundation for sustainable building materials

SAMPYO R&D Center is the industry’s first research institute specialized in building materials

Starting with a division specialized in R&D, the institute moved to a building in Gwangju, Gyeonggi-do in 2004. Dozens of professional researchers with masters and doctoral degrees are gathered here and drive the development of building materials and environment-friendly technologies in line with the trend of Industry 4.0.

We collaborate with other construction and admixture companies and university laboratories to develop various and applicable technology in on-site for the product production to meet the customer needs. In addition, constant study on advanced technologies and trends by releasing and issuing research papers at the relevant domestic and international conferences.

Major study results

- Developed special concrete, BLUECON

- Industrial property (no. of registration of patent: 88)

- Joint and entrusted research projects (no. of projects: 162)

- Published theses in Korea and overseas (no. of theses: 280)

Research area

Concrete field

We conduct a study on the most fundamental performance of concrete. We make products based on the continuous study on the development of high early strength, high flowability, reduction in drying shrinkage, and ultra-high strength. Our research team specialized in the architecture, civil engineering, chemistry, and polymer engineering areas perform about 10 research projects per year on average. The study area covers a special concrete used in RMC, a PC plant, and PST plant.

Our technological capability is more advanced than that of competitors when it comes to commercialization. We succeeded in commercializing special concrete products (high early strength, drying shrinkage, and flowability). On average, we apply for 5 to 10 patents per year and publish about 10 academic theses per year.

BLUECON

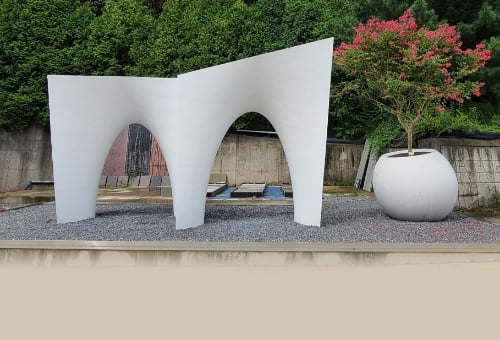

Ultra-high performance concrete (UHPC)

With ultra-high strength and high toughness, UHPC allows us to create any design by making it much thinner and smaller while not losing its unique texture as concrete. By applying a 3D printer technology, it is possible to express diverse textures and patterns, so it is possible to manufacture innovative sculptures, furniture, and exterior finishing materials.

We have many patents in this field in particular.

- “Method for Manufacturing Atypical Concrete Sculpture Using 3D Robot Molding Technology” (Registration no.: 102161279)

- “Method for Manufacturing Atypical Concrete Sculpture Using 3D Robot Molding Technology” (Registration no.: 102161279)

- Two design patents (Registration no: 301117222 and others)

Cement materials field

The Cement materials research unit develops binder related products for concrete including cement, blast furnace slag, and fly ash, and conducts tasks to continuously improve the performance of the products. Moreover, in line with the ESG management, the unit studies resource recycling to reduce environmental load and the expanded use of byproducts of a steel mill and combined heat & power plant. The team also developed special products applicable to various construction methods including reduction in heat of hydration and soil improvement while developing products customized to the needs of customers along with special products.

The unit establishes a method of recycling discarded resources, by-products from the existing industry, along with discovering new raw materials usable in concrete and mortar. The unit provides technical support on the evaluation of crack stability by analyzing the heat of hydration of mass concrete in relation to the supply of low heat blended cement. The unit also analyzes unknown samples and discovers application fields to contribute to a new construction base material business. The team focuses on resource recycling and product development to protect the environment.

Mortar field

Starting with the fundamental research on mortar, Sampyo makes an effort to develop products by applying the customer’s needs while developing regular (plaster, masonry) and functional products (tile, grout, and repairing material). Lately, we have been focusing on developing eco-friendly materials to respond to the toxicity of construction materials and environmental regulations. Also, we are developing high-performance mortar such as high flowability, high strength, and low shrinkage for customized use in various construction areas.