Logistics

Creating the foundation for sustainable building materials

We supply fast and precise logistics services through our Advanced Logistics Systems

SAMPYO is the leading company in construction logistics services and has established nationwide logistics networks with constant development and innovation since its foundation in 1966. Using our advanced logistics system we systematically manage the entire transportation process.

Our top priority is increasing corporate profits by reducing logistics costs and increasing logistics productivity by efficiently improving logistics and transportation infrastructure, which is the core component of corporate competitiveness. Based on the know-how accumulated through our long history, we will be positioned as Korea’s representative company for construction logistics by fulfilling the various needs of our customers and continued efficient logistics operations.

Customized logistics infrastructure

SAMPYO has secured dedicated facilities across the country, centering on Seoul, the country’s main metropolitan area, and provides the best service available to our customers through our stable supply of various vehicles.

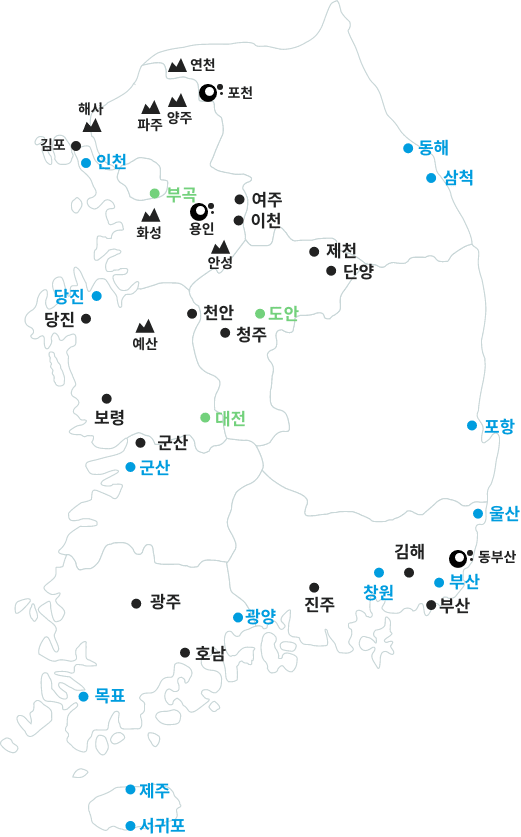

Logistics bases and locations

We have built a nationwide logistics network by running 26 inland stations, 13 marine stations, and three railway stations.

- Inland bases: 26 stations (Yangju, Hwaseong, Cheonan, etc.)

- Marine bases: 13 stations (Samcheok, Busan, Jeju, etc.)

- Railway bases: Three stations (Bugok, Daejeon, Doan, etc.)

Aggregate rock quarry

Aggregate rock quarry  Muck pile

Muck pile

Vehicles in operation

SAMPYO has established a stable transportation infrastructure by securing a total of 600 vehicles (self-owned, under contract, or under exclusive contract), including 400 dump trucks and 100 BCTs (Bulk Cement Trailers.) We can also effectively operate in any vehicle availability condition via our contracts with over 200 partner transportation companies.

Based on our national logistics network, SAMPYO will expand its transportation orders with large external clients such as power plants and steel mills, and contribute to reducing shipper costs by streamlining logistics through our Backhaul network. We are leading the domestic construction material logistics business by streamlining logistics networks with SAMPYO’s proprietary Fleet management & monitoring systems.

BCT

(Bulk Cement Trailer)

M/T

(Mixer Truck)

D/T

(Dump truck)

F/C

(Flatbed Trailer)

Marine and railway transportation

Marine transportation / Cargo handling operations

With production plants operating in the coastal areas, SAMPYO Cement is leading the domestic cement maritime transportation market by utilizing 11 dedicated ships and 3 general cargo ships. In addition, we swiftly supply slag and others materials generated from steel mills with our fleet of ships. We are also a stable source of sand, a base construction material extracted from beach sand to the metropolitan area.

Railway transportation

SAMPYO Cement has 230 cement freight trains and two locomotives, which transport cement to inland plants located in Bugok, Daejeon, and Doan via railway. Rail transportation enables us to deliver goods in a timely and eco-friendly manner, thus has become an important means of transportation for Sampyo.

Cutting-edge logistics system

In addition to providing transportation networks and infrastructure nationwide, SAMPYO also provides construction material logistics services employing our vehicles and equipment optimized for various construction material cargo,

Recently, to preemptively respond to changes in the ever-changing transportation market and improve our service quality, we are striving to establish a technology-based management system and strengthen professional manpower capabilities.

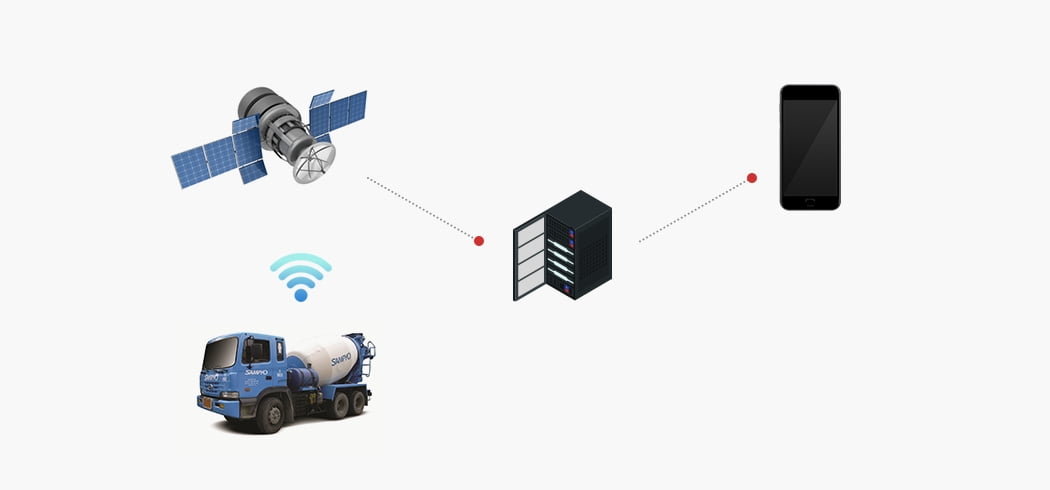

SAMPYO has developed from a traditional logistics market structure and now operates a technology-based advanced logistics system that combines high-tech technologies such as Mobile, GPS, and RFID.

By establishing a shipping automation system at each site across the country and operating an integrated management system to automate product processing & shipping and developing a logistics platform that connects all participants of the market into one network, SAMPYO is emerging as a leading logistics company in the 4th industrial revolution.

SAMPYO’s mobile system

Customers can now easily access information about their orders in real-time through smartphones. SAMPYO’s mobile system easily provides the current status of concrete cast sites, shipments, standby vehicles, and vehicles in shipment without the need to be on-site.

RFID-based logistics control system

SAMPYO provides quick and accurate logistics services through our RFID-based logistics control system, which tracks and manages the process from the origin to shipment in real-time. We are able to drastically reduce logistics costs by securing logistics hubs nationwide and streamlining vehicle operations.

Automated shipment system

SAMPYO is the first in the industry to have a state-of-the-art system that automatically operates the entire shipment process from vehicle dispatch to processing & shipment, issuance of delivery invoices, and product loading & unloading. The introduction of the automated shipping system has reduced shipping time by approximately 20% and allows customers to supply products faster and faster at the time they want.

Electronic invoice

By replacing paper invoice slips with electronic invoices, transportation management was able to be run more efficiently, and by implementing the automatic settlement system an online transportation management system was established.