We preserve the environment by recycling resources and leading the circular economy

Both by-products, blast furnace slag generated from the steel mill, and fly ash generated from the coal-fired power plant, are processed into fine powder and used as a substitute for cement due to their chemical characteristics. Instead of using ordinary cement, both by-products contribute to prevention global warming by further reducing CO2 emissions and consuming less thermal energy in cement production.

By recycling industrial by-products as a resource, we not only contribute to protect the environment, but also contribute to circular economy by creating high values from the wasted resources.

Over decades of leading the industry, SAMPYO has accumulated skillful human resources, various infrastructure and know-how. SAMPYO will establish itself as the largest circular economy company with continuous investments and development of eco-friendly products.

Building materials preserving the environment

Both by-products, “blast furnace slag” a non-metal by-product generated from manufacturing steel in the steel mill, and “fly ash” a byproduct collected of the combustion of dust coal in a coal power plant through dust collector, can be used as substitutes for cement as they are comprised of the chemical components of limestone and quartz sand.

When slag and fly ash are processed into fine powder, they are turned into cement products with low CO2 emissions or slag cement products where ordinary cement is blended with fine powder of blast furnace slag. Both slag and fly ash reduce generating the CO2, one of the greenhouse gases. They are an eco-friendly construction material contributing to prevent global warming.

The largest production capacity in Korea

We are proud of our top production capacity in the industry and high market share (about 30%), producing 2.4 million tons of slag products and 2.1 million tons of fly ash products annually.

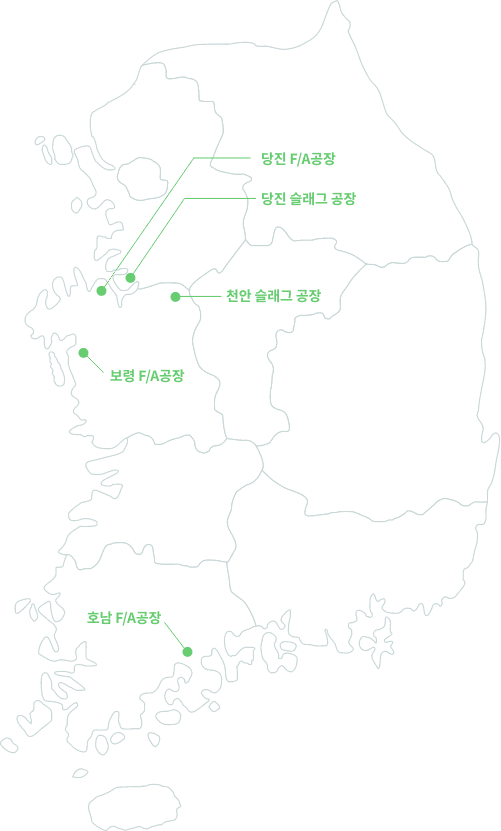

Beginning with the Dangjin fly ash plant in 2001, we went on to establish fly ash plants in Boryeong and the Southwestern region (Honam) of Korea. We also established production and supply networks in each area by building the Dangjin slag plant (2012), Cheonan slag plant (2014), etc. By doing so, we are able to stably supply fly ash, blast furnace slag fine powder, and blast furnace slag cement.

Production and supply network in each area

Dangjin fly ash (FA) plant/ Dangjin slag plant, Boryeong FA plant/

Cheonan slag plant / Honam FA plant

Outstanding technology and know-how

We are developing high-quality products including low heat cement through constant research. In particular, the cement we have developed with slag has been publicly recognized through its obtainment of the “Green Technology” certification from MOLIT, the “Good Recycled Product (GR)” certification from the Korean Agency for Technology and the Standard (KATS) certification under the Ministry of Trade, Industry and Energy (MOTIE). We also retain multiple patents related to our products and production equipment.

Green Certification

GR certification (for excellent recycling products)