Environment, Healthy and Safety (EHS)

Envisioning the foundation for a sustainable future

We maintain the optimal work environment system for safety

The task of environment, health, and safety (EHS) is one that SAMPYO Group is focusing on as its utmost priority among other business activities, and it is also an essential element of our corporate philosophy. We invest efforts to reduce the danger of accidents and injuries and minimize the risk of having occupational diseases through effective prevention measures. With wide-ranging training activity and safety measures optimized to each workplace, we will continue our efforts to maintain a safe workplace free of accidents.

Our EHS policy

We practice the following to secure the safety of all our employees and protect the environment.

01. SAMPYO believes that the life and health of all workers are of the utmost priority and thus maintain optimal work environment and facilities.

02. By establishing the advanced EHS system and observing regulations, SAMPYO minimizes the safety impact on the overall management activity and continuously strives to improve safety. SAMPYO fulfills corporate social responsibility by actively participating in the environmental preservation of the community in addition to the protection of our workplace.

03. Through continuous education and training, SAMPYO ensures that all of our partner companies as well as our executives and employees understand and practice the EHS measures, so that they do their best to create a safe and comfortable workplace.

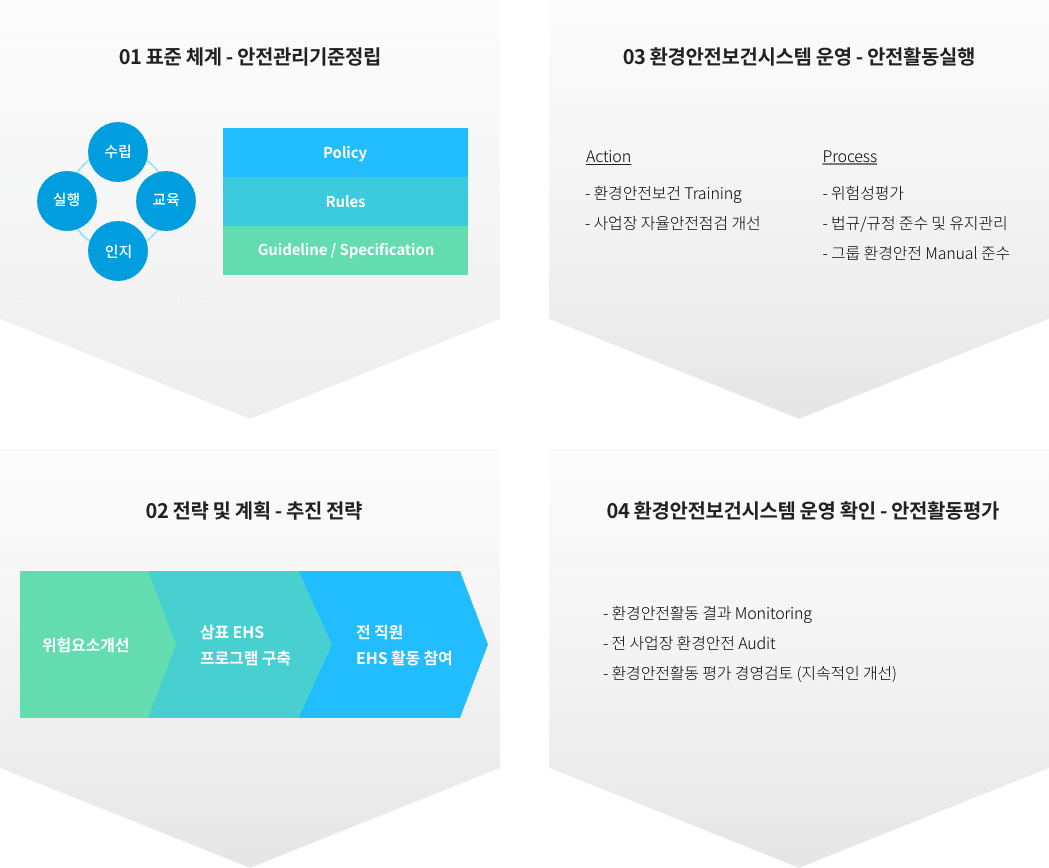

EHS management system

With the objectives of industrial accident prevention and creation of a pleasant work environment, SAMPYO Group sets the goal of maintaining and increasing the safety and health of our workers. To attain the goals, we effectively allocate physical and human resources throughout the company after prescribing the procedures on organization and responsibility. We also continue to practice sustainable EHS management.

Our golden rules : Safety

We defined the safety rules (Eight Dos and Five Don’ts) that our employees and partners must follow. The rules are designed based on past accident cases, and we are strengthening our safety regulations customized to the condition of each workplace. With intensive training, we work to ensure that all workers are well aware of danger areas in order to prevent accidents in advance.

Our basic safety rules (Eight Dos and Five Don’ts)

8 Dos

- Must wear safety protective equipment while at work.

- Always maintain a tidy work environment before and after work.

- All work must be conducted after obtaining an approval to start work.

- Workers must thoroughly observe the safety work procedure when conducting the lock-out, tag-out, and try-out (LOTOTO) work.

- Secure a moving passage and space when working.

- When conducting work at a height of over 2.0 m above ground, workers must fasten a safety belt clip.

- 7. When working with fire, workers must manage the fire sparks and dispatch a fire supervisor.

- When workers must work in an enclosed space, workers must first obtain a work order, gas measurements and dispatch a supervisor

5 Don’ts

- Access, unauthorized operation or repair are all prohibited when equipment is in operation.

- Unauthorized removal or dismantlement of safety facilities, devices, etc. is prohibited.

- When conducting heavy lifting work with a crane, etc., access to the surrounding areas is prohibited.

- It is prohibited to approach within the operation radius of heavy equipment work (excavators, loaders, etc.).

- Unauthorized access to electric appliances and facilities is prohibited.